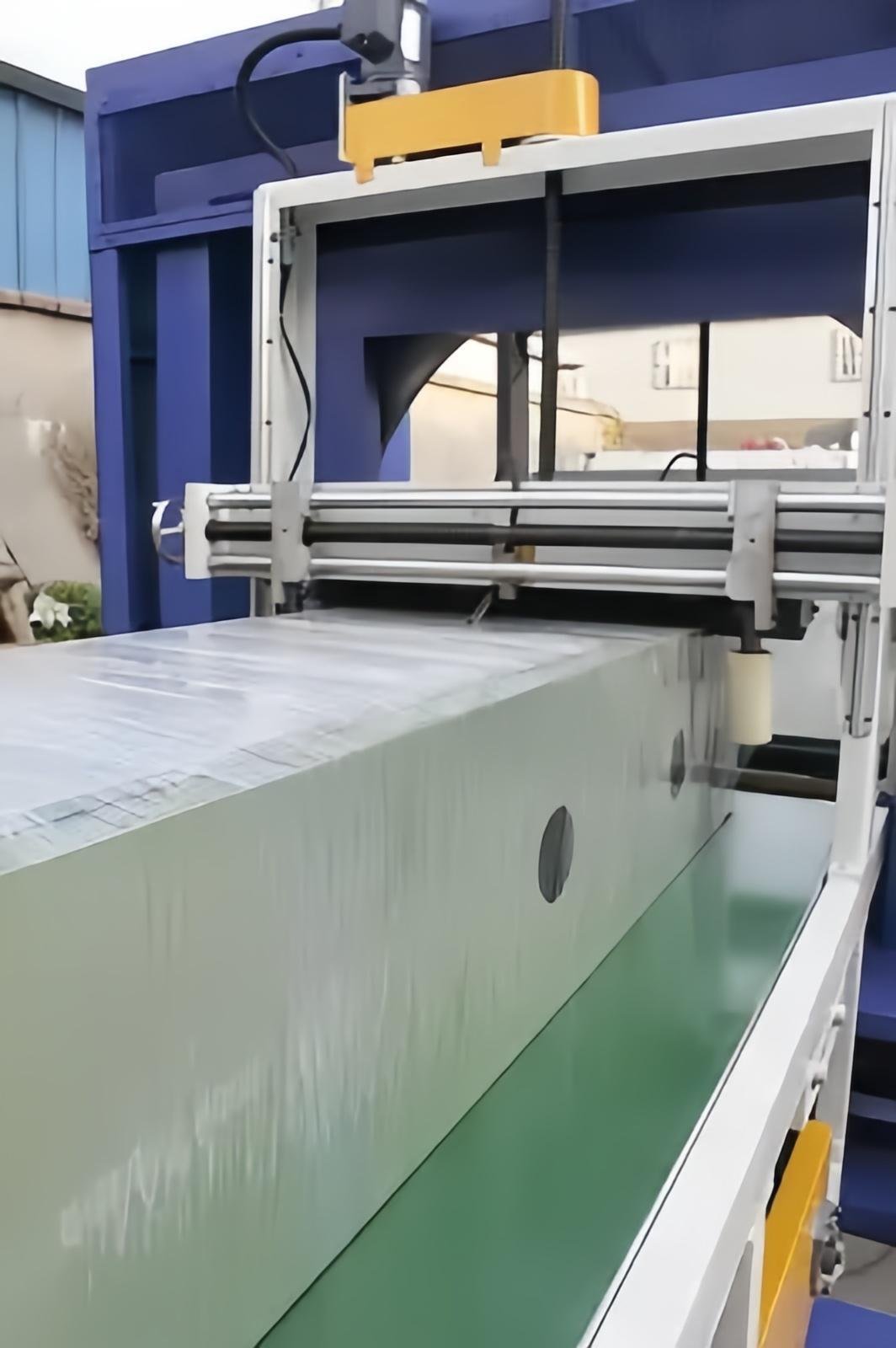

E1000 Horizontal stretch wrapping machine

The Orbital Ring Stretch Wrapper & Film Wrapping Machine is a versatile, efficient solution for packaging long, bundled, or delicate items such as trays, profiles, and fragile goods. Combining automation with sustainability, it enhances packaging speed, reduces labor costs, and ensures product protection.

Key Features:

Reinforced Aluminum Ring: Durable design with adjustable speed and friction for secure, consistent wrapping.

Automatic Material Handling: Film feeding, cutting, and tension adjustments streamline the wrapping process.

Advanced Conveyor System: Soft-touch conveyor surfaces protect products while ensuring smooth transport.

Special Features

Related video

The E1000 Horizontal Stretch Wrapping Machine is built for large-scale industrial applications, ideal for wrapping oversized and elongated items like panels, pipes, and profiles. With advanced features such as adjustable tension, variable speed, and robust construction, it ensures consistent and secure packaging. The E1000 enhances operational efficiency and provides reliable product protection du

Orbital Ring Stretch Wrapper & Film Wrapping Machine

Overview

The Orbital Ring Stretch Wrapper & Film Wrapping Machine is a versatile, high-speed solution designed to reduce labor costs and improve packaging efficiency. As a key component in sustainability initiatives, this machine ensures optimal wrapping speed while providing superior protection for bundled, boxed, tray, and profile packages.

Equipped with advanced technology, the machine adapts to the specifications of each load, offering customizable features that meet diverse packaging needs without compromising product integrity.

Key Features

1. Spiral Stretch Wrapping Station

Reinforced Aluminum Ring: A 60mm wide aluminum ring on a robust structure ensures long-lasting performance.

Powerful Motor with Gearbox: Delivers consistent power for efficient operation.

Integrated Wrapping Station: Arrives pre-assembled and ready to use, eliminating the need for re-installation.

Adjustable Friction: Ring and driving wheel friction are easily customizable for precise control.

Inverter-Controlled Ring Speed: Allows speed adjustments to match various packaging requirements.

Soft Start/Stop and Jog Mode: Ensures smooth operation and reduces mechanical stress.

Automatic Position Reset: Sensors return the wrapping position to the initial point automatically.

Easy Material Reloading: Simplifies operation with user-friendly film reloading.

Adjustable Packing Tension: Customizable to accommodate different package sizes and materials.

Material Compatibility: Works with a variety of packaging materials.

Safety Shielding: Protects operators by enclosing moving parts and machinery structure.

Adjustable Overlap Rate: Customizable from 10% to 90% to meet specific wrapping needs.

Touchscreen Controls: Enables quick adjustments of packaging data and parameters.

2. Conveyor System

Surface Protection: Conveyor design prevents surface damage during transportation.

Automatic Infeed and Outfeed Systems: Streamlines the flow of products into and out of the wrapping station.

Motor-Driven with Speed Control: Gearbox-equipped conveyors with inverter-controlled speed for flexibility.

Object Detection Sensors: Precisely detects loads to trigger operational actions.

Customizable Design: Configurable to support different load infeeding methods.

3. Automatic Mechanical Hand

Heat Cutting & Knife Cutting Options: Available in two versions to suit diverse material requirements.

Synchronization with Ring Speed: Coordinates with cylinder action time for seamless operation.

Automatic Material Clamping: Prepares wrapping materials for the next cycle without manual intervention.

Adjustable Parameters: Customizable operation settings to meet specific packaging goals.

4. PLC & HMI Control System

Intuitive Interface: Touchscreen interface allows easy adjustments for ring speed, roller speed, package size, and process settings.

IoT Monitoring: Remote troubleshooting support ensures operational efficiency.

Photocell Sensor: Detects and adjusts wrapping position with precision.

Independent Control Panel: Simplifies maintenance and operational tasks.

Reinforced Wrapping Options: Adjustable head and end wrapping settings for added protection.

Remote Control and Assistance: Enables long-distance operation and support.

5. Press Down Device

Side Protection: Manually adjustable devices prevent product shaking during wrapping.

Top Press Device: Soft material protects fragile surfaces, such as glass.

Dual Pressing Devices: Located on infeed and outlet conveyors for enhanced stability.

Programmable Action Time: Adjustable pressing actions tailored to different packaging purposes.

Versatile Protective System: Suitable for objects with various frames, structures, or non-planar surfaces.

Optional Features

Special Tension Control Carriage

Motorized Tension Control: Provides strong and tight wrapping for secure packaging.

Adaptability: Supports stretch film for both large and small packages while ensuring smooth, aesthetically pleasing results.

Benefits

1. Efficiency and Cost Reduction

Automates the wrapping process, significantly reducing labor input.

Enhances packaging speed, saving time while maintaining quality.

2. Superior Product Protection

Ensures secure packaging without damaging or crushing goods.

Adjustable tension and overlap rates accommodate various package types and sizes.

3. Versatile Applications

Suitable for bundling, boxing, trays, profiles, and other long or oddly shaped items.

Designed for diverse industries, including logistics, construction, and manufacturing.

4. Enhanced Safety

CE-standard safety shielding protects operators during operation.

Soft start/stop and jog features reduce mechanical stress, ensuring smooth handling.

5. Sustainability

Reduces material waste and supports sustainability initiatives through efficient resource use.

Applications

The Orbital Ring Stretch Wrapper & Film Wrapping Machine is ideal for:

Bundle Packaging

Boxes and Trays

Profiles and Frames

Elongated Items

Fragile Goods

Technical Data

| Parameter | Specification |

|---|---|

| Object Size | Length: >1000mm, Bundle OD: 400-1000, Weight: 50-400kg |

| Infeed Conveyor | 2000mm L × 1200mm W |

| Outfeed Conveyor | 2000mm L × 800mm W |

| Material | LLDPE Stretch Film / Paper / Woven Width: 100-500mm, OD: 100-250mm, ID: 50mm (Let me know if you need another size) |

| Air Supply | 5~8kgf/cm² |

| Conveyor Speed | 3~12m/min |

| Ring Speed | App. 10-60r/min |

| Machine Size | App. L4800 x W1800 x H2000mm |

| Power Output | About 4.5kw |

| Power Voltage | AC 380v, 50Hz, 3Phase |

| Control Power Voltage | ADC24V |

Contact us to learn more and customize your machine.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635