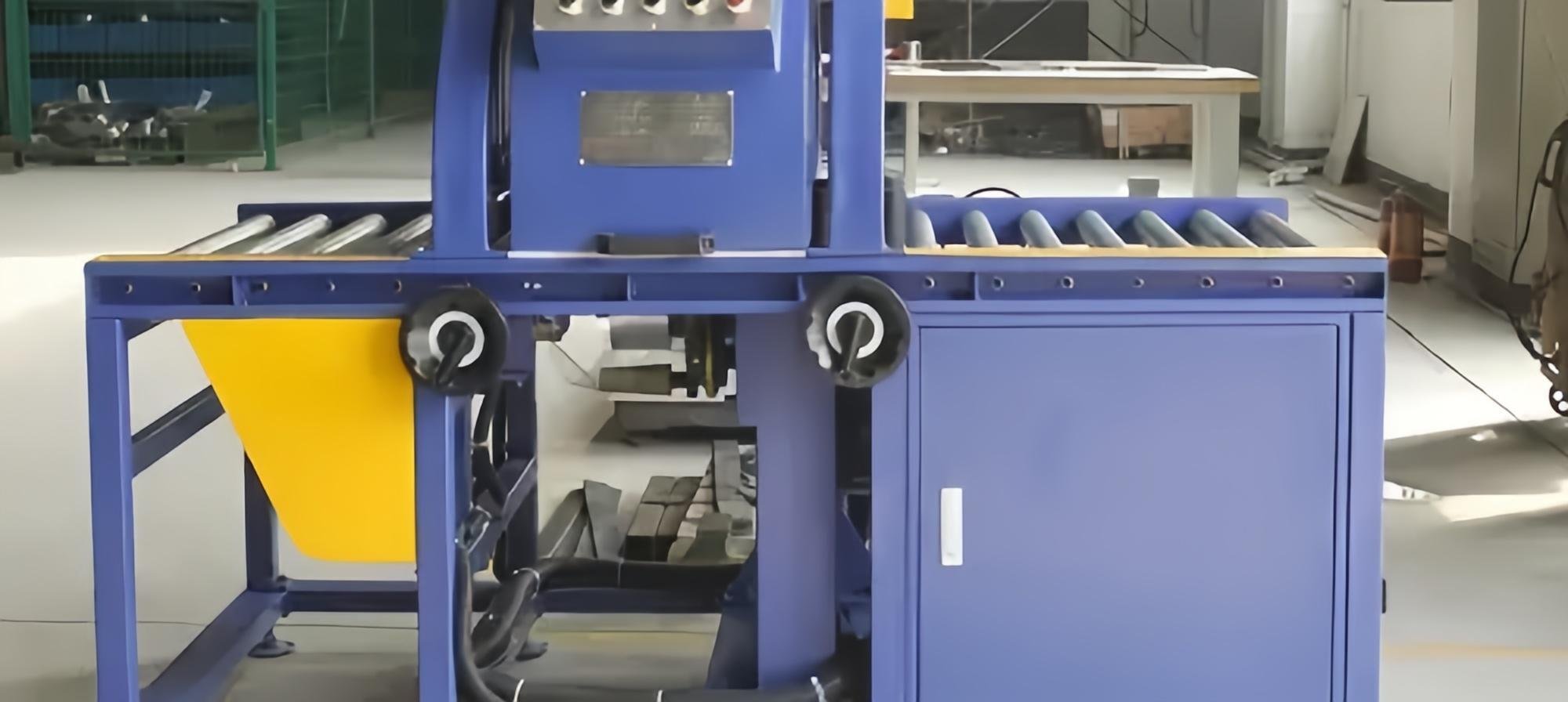

E100 Horizontal stretch wrapping machine

The FHOPE Fully Automatic Horizontal Wrapping Machine E100 is a cutting-edge packaging solution designed for exceptional performance, efficiency, and versatility. Ideal for automating production lines and reducing operating costs, it offers precise, reliable, and cost-effective packaging for various industries.

Core Features:

High-Efficiency Automation: Advanced PLC control and precise sensors enable fully automated operations, ensuring fast and accurate packaging.

Wide Applicability: Suitable for logistics, warehousing, and manufacturing industries, packaging items like oil pipes, doors, windows, and panels.

Precise Wrapping: Even and tight film application with adjustable parameters for single or double-layer wrapping.

Cost Savings: Reduces labor input and material waste, while enhancing packaging quality to minimize product damage.

Special Features

Related video

The E100 Horizontal Stretch Wrapping Machine is designed for wrapping elongated and irregularly shaped products such as pipes, rods, and profiles. Featuring a compact and robust design, it provides consistent stretch wrapping with adjustable tension and speed settings. Ideal for industrial use, the E100 enhances packaging efficiency and ensures product protection during storage and transport.

E100 Automatic Wrapping Machine, a compact and efficient automated packaging solution, designed to enhance packaging efficiency. Combining precise control, wide applicability, and cost savings, it easily meets the fast and accurate packaging needs of various items.

FHOPE Fully Automatic Horizontal Wrapping Machine E100, as a reliable assistant in the modern packaging industry, offers exceptional performance and high operational efficiency, bringing significant economic benefits to enterprises. It is the ideal choice for achieving automated production and reducing operating costs.

Core Features:

High-efficiency Automation:

The automatic wrapping machine uses an advanced PLC control system combined with precise sensors and actuators to achieve fully automated operation. Users only need to set packaging parameters, and the machine will automatically complete the packaging tasks, greatly improving packaging speed and accuracy.

Wide Applicability:

This machine can be applied across multiple industries and fields, such as logistics, warehousing, and manufacturing. Whether it's metal, wood, plastic, textiles, or other types of long, straight items like oil pipes, doors and windows, or panels, the automatic wrapping machine provides a perfect packaging solution.

Precise Packaging:

With its precisely designed wrapping mechanism, the automatic wrapping machine ensures that the packaging film is wrapped evenly and tightly around the surface of the items, forming a secure packaging layer. Additionally, the machine supports various packaging modes and adjustable parameters, such as single-layer or double-layer material wrapping, to meet different product packaging needs.

Cost Savings:

By reducing labor input and minimizing packaging material waste, the automatic wrapping machine effectively lowers packaging costs. Moreover, the improved packaging quality helps reduce the risk of product damage during transportation and storage, further lowering operational costs for the enterprise.

Easy Maintenance:

The machine is designed with a reasonable structure, making it easy to maintain and service. Additionally, the manufacturer provides comprehensive after-sales service and technical support, ensuring that users receive timely assistance and guidance during operation.

Machine Color: Customizable

Options:

Custom brand parts

Conveyor type: PVC / roller / chain / chain plate

Safety interlock

Conveyor belt length

| Technical parameter | |

| Model | E100 |

| Power supply | 380v 50Hz 3Phase |

| Total power | About 2.5kw |

| Product length | >1000mm |

| Product OD (Width) | 50-100mm |

| Weight | 8-100kg |

| Infeed conveyor length | 2000mm |

| Outfeed conveyor length | 2000mm |

| Packing material | LLDPE stretch film/ PE film/ PVC |

| Packing material size | Width:50-100mm OD:100-200mm ID :50mm |

| Overlap rate | 10%-90% |

| Ring speed | About 20-90r/min |

| Roller speed | About 5-15m/min |

| Air supply | 4-7kgf/ ㎡ |

Contact us to learn more and customize your machine.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635